While their teeth are curved the ends section of each tooth are coplanar with the axis and the middle part of each tooth is circumferentially swept around the gear. Precision Gears Per Design Bevel Sets Parallel Axes Gears.

Zerol bevel gear design Written By barrettellies74281 Monday March 28 2022 Add Comment Edit.

. Serving customers in the Aerospace and Industrial Markets. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. So the gear face line and the gear pitch line are coincident.

They have the combination of advantages of straight and spiral bevel gears. To develop the selected Gear 9. Hypoid type spiral type zero spiral type and straight type bevel gears.

A reliable source over 50 years for precision Bevel and Parallel Axes Gears. Bevel Gear Terminology. Figure 1 shows an illustration of a Zerol bevel gear set and a cross-sectional drawing.

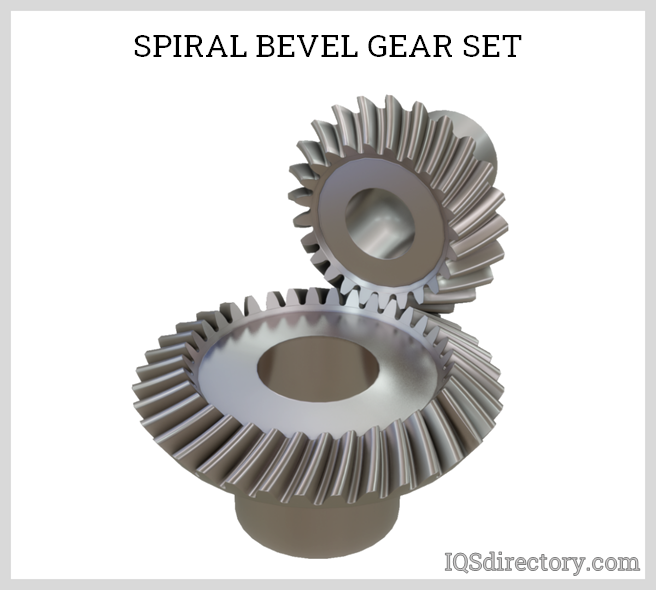

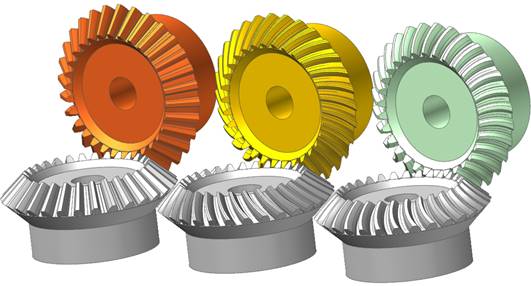

The rule of thumb curvature shown here can be applied to either the pinion or the gear and works for Zerol bevel spiral bevels and hypoids. For peripheral speeds upto 1000 feet per minute where maximum smoothness and quietness are not primary considerations straight and Zerol bevel gears are recommendedFor such applications plain bearings may be used for radial and axial loads although the use of anti-friction bearings are always preferable. Spiral bevel gears Figure 5716 have curved oblique teeth that contact each other gradually and smoothly from one end of the tooth to the other meshing with a rolling contact similar to helical gears.

The helical design produces less vibration and noise than conventional straight-cut or spur-cut gear with straight teeth. Hypoid bevel gearsThese gears are similar to spiral bevel except that the pitch surfaces are hyperboloids rather than cones. CALL US 630 543-6640.

Sub-zero temperatures using special application. Provides the standards for designing straight bevel zerol bevel spiral bevel and hypoid gears along with information on fabrication inspection and mounting. Figure 814 Zerol Bevel Gear At the point on the tooth line where it intersects the pitch cone generating line at angle β if the perpendicular cross section is drawn then the equivalent spur gears number of.

To design that Bevel Gear III. There are four types of bevel gears are available in general mechanical design. Zerol bevel gears trade marked by the Gleason Co are spiral bevel gears in which the spiral angle is zero at the middle of the face width.

Our products and services support the production of profitable gearing technology. The continuous pitch line contact of spiral bevel and hypoid gears makes it practical to obtain smooth performance with a smaller number of teeth in the pinion than is possible with straight or Zerol bevel gears. Spiral bevel and hypoid gears are also recommended for large reduction ratios to reduce the overall size of the installation.

Design Manual for Bevel Gears. Ad MISUMI Partners with You Delivers Components For Your Applications. All the circular arc gears other than Zerol gears are sometimes called helical bevel gears.

For miter gears input and output bevel gears have the same number of teeth. Shop Online at MISUMI Today. To solve a problem related to Bevel Gear II.

Per definition Zerol gears are manufactured in a single-indexing process applying a standard tooth taper as shown in. AGMA 20203 1965 System for ZEROL Bevel Gears AGMA 20803 1979 System for Straight Bevel Gears AGMA 20904 1982 System for Spiral Bevel Gears AGMA 33001 1972 Design Manual for Bevel Gears The standard was revised in 1994 to include all currently used hypoid design methods. Usually the manufacturer of the bevel gear.

Straight and Zerol Bevel gear. Figure 1Zerol bevel gear geometry. Ad Shaft Mount Gearbox Frame Sizes 2 to 5 with 91 151 and 251 Ratios.

A right-hand gear always mates with a left-hand pinion. Zerol bevel gears can be introduced as a kind of spiral bevel gears which also have special teeth but with a zero. On a hypoid bevel gear the pitch angle is hyperbolic instead of conical and the pinion can be offset either below or above the gear center.

Bevel gears can include straight spiral Zerol hypoid and Spiroid to address the differences between each one is beyond the scope of this guide. The related zerol bevel gear design pageyou can find more similar zerol bevel gear design from YQ-ChinaTransmissionschina zerol bevel gear design manufacturerWe provide you excellent products buy services. The fatigue failure analysis based on stress-life method is especially useful for a wide range of gear design applications and.

Ad Equip your team with the highest quality tailored gear manufacturing solutions. Some typical bevel gear The most common gear-cutting processes include hobbing broaching milling and grinding. Zerol bevel gears are very similar to a typical bevel gear.

By nature bevel gear design is highly complex. A left-hand gear always mates with a right-hand pinion. Covers preliminary gear design parameters blank design including standard taper uniform depth duplex taper and tilted root.

Gears are commonly made from metal plastic and wood. STRAIGHT BEVEL GEAR SPIRAL BEVEL GEAR ZEROL BEVEL GEAR HYPOID BEVEL GEAR LECTURE from DESIGN 2 at Polytechnic University of the Philippines. The main objectives of this project work are- I.

In general when the concept of bevel gear is spoken people generally think of the straight type of bevel. Zerol bevel gear design If subtlety isnt your factor Choose anything with a little more blingFrom terms to jewels as well as chains theres no limit into the 3D factors you can attach in your nails so get Inventive and Allow loose. The teeth are curved teeth at an angle allowing tooth contact to be gradual and smooth.

Spiral bevel gears are smoother and quieter in operation than straight bevel gears primarily due to a design that. About Zerol Bevel Gears Characteristics. Gears and Pinions - Manufacturer of bevel gears spiralangularhypoidstraight bevel gearsspline shaftsquality design.

Get High Quality at an Efficient Cost in Less Time. In essence Zerol Bevel Gears are Spiral Bevel Gears with a spiral angle of zero. Ate the desired crowning see also General Explanation of Theoretical Bevel Gear Analysis.

Zerol Bevel Gear Design. A zerol bevel gear also has curved teeth but they are not angled in a spiral so the teeth align with the axis. Because these types of bevel gears are basically conical in shape they all have an optimum position for best performance.

Zero Bevel Gear For Automobile Industry Promod Gears Id 21303994712

Pdf Design And Analysis Of A Spiral Bevel Gear Semantic Scholar

Mitcalc Bevel And Hypoid Gears According Iso 23509

Types Of Bevel Gears And Geometric Calculations With Calculators

Bevel Gear What Is It How Does It Work Types Uses

Concept Of Spiral Bevel Gear Hobbing Download Scientific Diagram

0 comments

Post a Comment